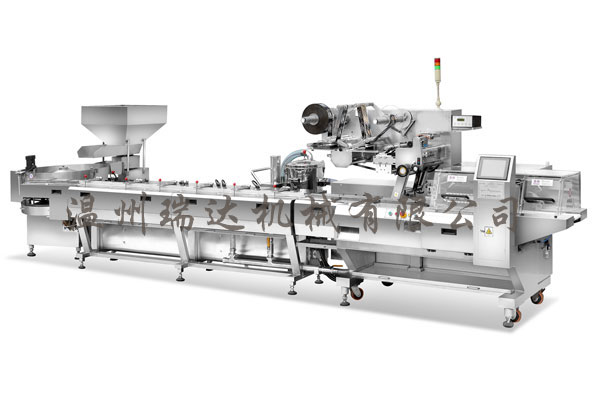

Pillow packing machine has fault self-diagnosis function

Pillow packing machinery has fault self-diagnosis function

1, double motor panasonic double frequency conversion, computer PLC control, bag length is set and cut, no need to adjust air, one step in place, save time and film.

2. Push button man-machine interface, all Chinese/English menus, convenient and fast parameter setting.

3, fault self-diagnosis function, fault at a glance.

4. High sensitivity photoelectric eye color standard tracking, making sealing and cutting position more accurate.

5, pillow packaging machine temperature independent PID control, better suitable for a variety of materials envelope.

6, positioning stop function, non-stick knife, no cost film.

7, the transmission system is simple, reliable work, more convenient maintenance.

8. All controls are realized by software, so that convenient function adjustment and technical upgrade will never lag behind.

Pillow packing machine working principle

Pillow packing machine is a very strong packaging capacity, and can be suitable for a variety of specifications for food and non-food packaging continuous packaging machine. It can not only be used for the packaging of non-trademark packaging materials, but also can be used for high-speed packaging with pre-printed trademark drum materials. In the packaging production, due to the error between the positioning color labels printed on the packaging materials, the influence of the stretching of the packaging materials, mechanical transmission and other factors, the predetermined sealing and cutting parts of the packaging materials may deviate from the correct position, resulting in error.