Pillow packing machine is a typical mechatronics product

Pillow packing machine is a typical mechatronics product

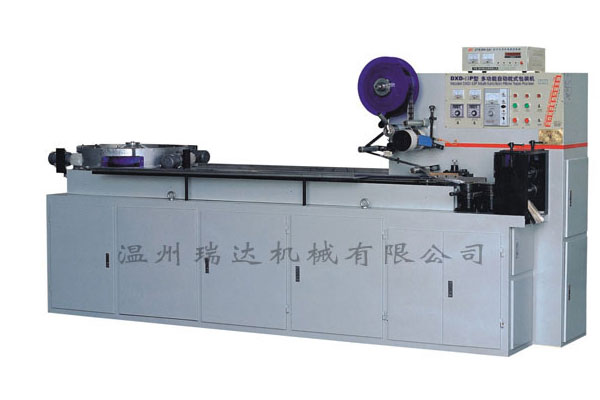

Pillow packing machine is a typical mechatronics product, the whole system includes mechanical transmission, electronic heating, color calibration control. Combined closed-loop control with slip difference is adopted in the positioning control, which has high precision and real-time adjustment function. The variable speed principle is adopted in the hot cutting mechanism to ensure the reliability of tail seal and cutting. Because of the organic combination of mechanical and electrical, the system has higher performance. The concept of time ruler is put forward for the first time in the application of single chip microcomputer, which greatly expands the timer resource and is equivalent to expanding the function of single chip microcomputer, which has practical significance to its application.

Packaging machine is widely used in food packaging and other fields, is the needs of modern industry, it takes the packaging film as the processing object, can be fast food noodles, biscuits and other packaging products for packaging, whether to improve the economic benefits or improve the health quality of products have been applied attractive, so it has been more and more widely used.

Pillow packaging machine as a typical mechatronics products, including the following parts: mechanical transmission, electronic temperature control, color calibration control. The function of mechanical transmission is to provide power for the whole machine. Electronic temperature control adopts electronic heating rod and thermocouple to form closed-loop control. Color calibration control to ensure the packaging film to the packaging of the correct packaging.

Pillow packing machine working principle

Pillow packing machine is a very strong packaging capacity, and can be suitable for a variety of specifications for food and non-food packaging continuous packaging machine. It can not only be used for the packaging of non-trademark packaging materials, but also can be used for high-speed packaging with pre-printed trademark drum materials. In the packaging production, due to the error between the positioning color labels printed on the packaging materials, the influence of the stretching of the packaging materials, mechanical transmission and other factors, the predetermined sealing and cutting parts of the packaging materials may deviate from the correct position, resulting in error.